(501) 319-5420

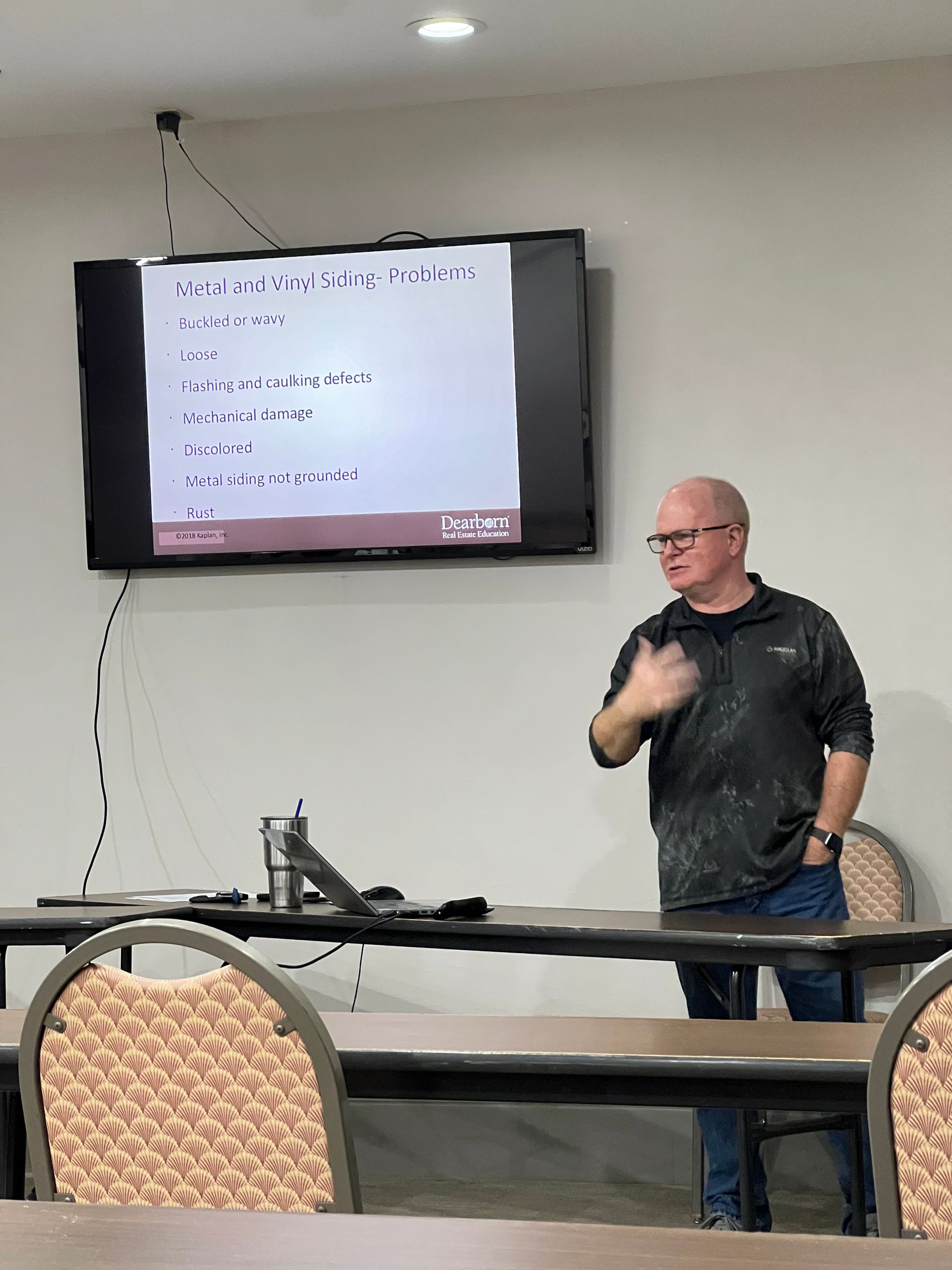

Inspecting Electrical Systems

Inspecting Electrical Systems: Safety Precautions and Common Findings

Electrical systems are the lifeblood of modern buildings, powering everything from lights to computers, and their safety is paramount. Regular inspections are crucial for ensuring these systems are running safely and efficiently. This guide will break down the key components of electrical inspections, outline the essential safety precautions, and discuss common findings that inspectors encounter.

### Understanding Electrical Inspections

Electrical inspections involve a thorough check of all electrical systems within a building or facility. These inspections are conducted to identify any potential hazards, ensure compliance with electrical codes, and verify that all electrical work meets the required standards. Inspectors look at a variety of components, including wiring, outlets, panels, and appliances.

### Safety Precautions

Safety is the top priority during any electrical inspection. Here are some precautions that inspectors and facility managers should always follow:

1. **Turn Off Power**: Before beginning an inspection, ensure that the power is turned off to avoid electric shock.

2. **Use Protective Equipment**: Inspectors should wear appropriate personal protective equipment (PPE), such as gloves and eye protection.

3. **Follow Lockout/Tagout Procedures**: To prevent accidental energizing of the system, lockout/tagout procedures must be strictly adhered to.

4. **Test for Voltage**: Before touching any wires or components, use a voltage tester to ensure the power is indeed off.

5. **Check for Proper Labeling**: All electrical panels and circuits should be clearly labeled to avoid confusion and potential hazards.

### Common Findings

During inspections, there are several common issues that may be discovered:

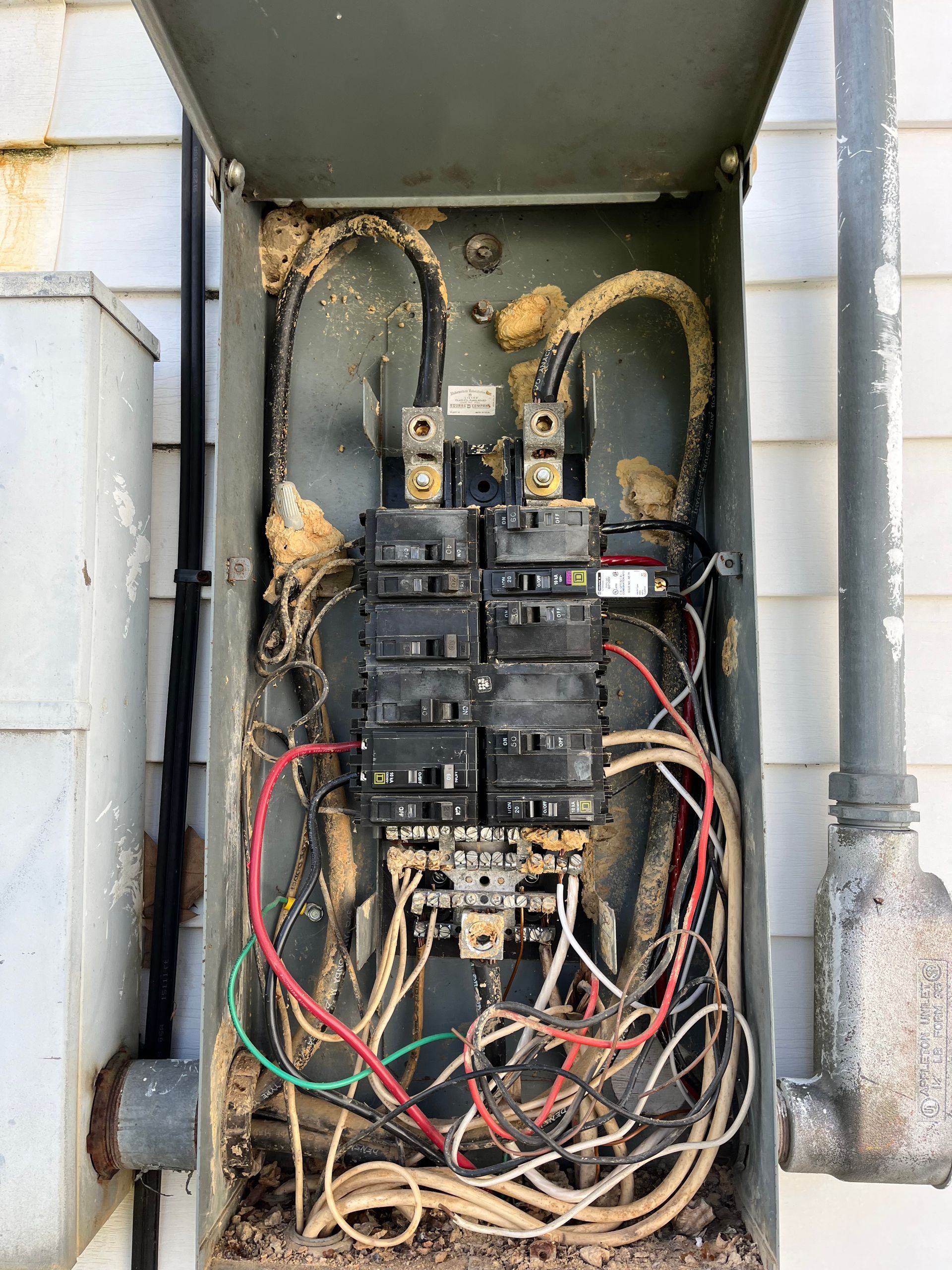

- **Faulty Wiring**: Inspectors often find wiring that is frayed, exposed, or not up to code, which can pose serious fire and electrocution risks.

- **Overloaded Circuits**: Circuits that have too many devices connected can overheat and potentially cause fires.

- **Outdated Equipment**: Older electrical panels and equipment may not meet current safety standards and could require updating or replacement.

- **Improper Grounding**: Proper grounding is essential for safety, and a lack of it is a frequent issue.

- **Damaged Outlets**: Outlets that are loose, damaged, or improperly installed can lead to shocks and fires.

### Best Practices for Electrical Safety

To maintain a safe environment, regular scheduled inspections are a must. Here are some best practices:

- **Conduct Routine Inspections**: Schedule and perform regular inspections to catch and mitigate issues early.

- **Train Employees**: Ensure that all employees are trained in electrical safety and understand the risks involved.

- **Implement Surge Protection**: Use surge protectors to prevent damage to electrical equipment from voltage spikes.

- **Stay Updated on Codes**: Electrical codes and standards evolve, so it's important to stay informed and ensure compliance.

### Conclusion

Electrical inspections are a critical aspect of building maintenance, ensuring the safety and efficiency of electrical systems. By understanding the inspection process, adhering to safety precautions, and being aware of common findings, facility managers and inspectors can help prevent accidents and maintain a safe working environment. Remember, electricity is a powerful tool that demands respect and caution at all times.

Electrical safety inspections are just part of the Home Inspectors job description. For more information, contact us here.

service Area

Arkansas

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: